|

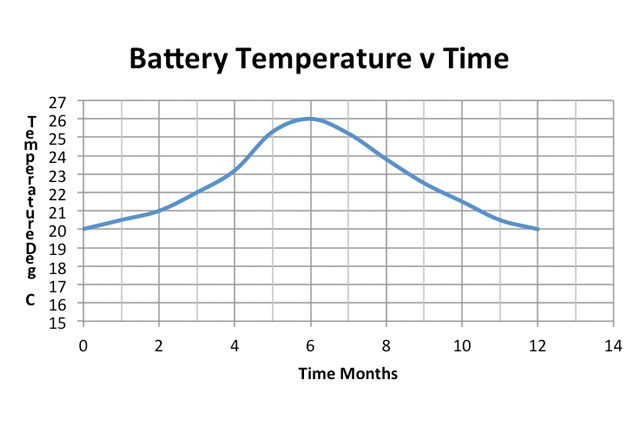

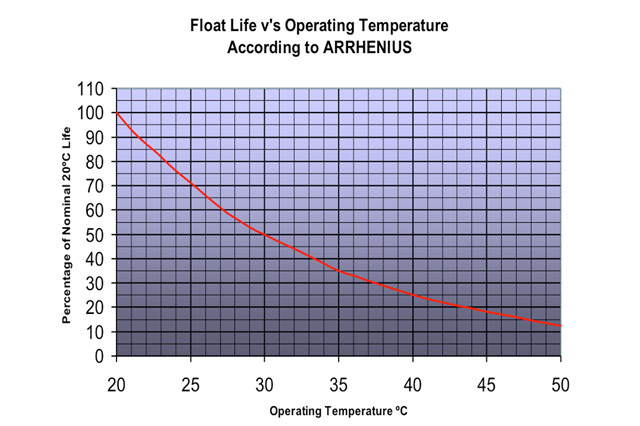

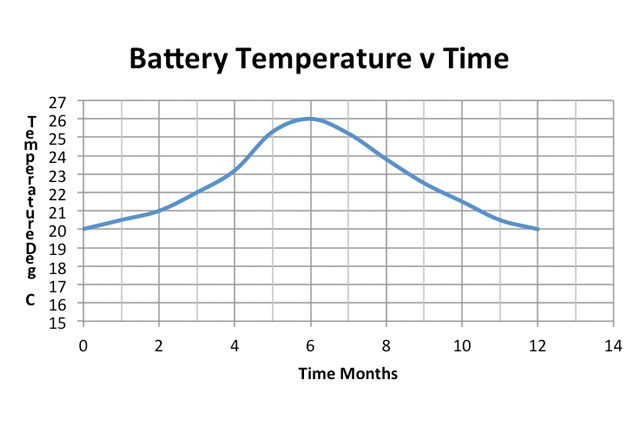

众所周知,所有铅酸电池在较高温度下运行时,寿命都会缩短。不管是什么类型的铅酸蓄电池,也不管是谁生产的,都是如此。该效应可以描述为阿列尼乌斯方程。 Svante Arrhenius 是一位瑞典科学家,他发现铅酸电池的寿命会受到温度变化的影响。他确定温度每升高 10oC,电池寿命就会减半。因此,举例来说,如果在 15oC 时寿命为 30 年,那么在 25oC 时寿命将为 15 年。该方程式还表明,在 5oC 时,寿命将为 60 年,但不幸的是,当电池非常旧(通常超过 30 年)时,其他因素就会发挥作用,而 Arrhenius 方程式仅在大约 15oC 和 40oC 之间对工作电池真正有效。 为什么生命会减少?有许多相互作用的电化学效应,但其中一个主要原因是对于浮充充电器施加到电池的任何给定恒定电压,都会产生浮置电流。如果温度升高,铅酸电池将接受更多电流,如果我们接受正常寿命结束是由于栅极腐蚀,那么如果温度升高 10oC,寿命将减半,因为每 10oC 电流增加一倍温度升高。还表明,水会通过容器壁蒸发,如果温度升高,则蒸发也会增加。这可能会导致某些 VRLA AGM 和 VRLA GEL 类型的电池变干。然而,这是一个复杂的主题,无法轻易计算和应用来预测寿命。无论如何,质量好的铅酸电池通常不会因干涸而失效。干燥与通风类型无关,我们可以使用 Arrhenius 方程来估算工作温度与设计温度不同时的寿命。 在欧洲,通常会引用在 20oC 的连续温度下运行时的电池寿命。如果温度为 10oC 并持续 3 个月,这不会将总寿命缩短一半,而只会缩短预期 20oC 寿命的百分比。但是,如果在 21oC 而不是 20oC 的整个生命周期内运行,寿命将减少近 10%。我们在提及生活时也必须小心,将“设计生活”和“现实生活”区分开来。VRLA AGM 电池的设计寿命可能为 10 年,但即使在 20oC 下连续运行,实际寿命也将接近 8 年。同样,有些人引用高性能 planté 电池的设计寿命为 25 年,但有许多此类电池在 30 多年后仍在使用的例子。 我们还应该考虑电池配置和热管理。例如,如果将电池放置在高度很容易超过 2m 的 6 层支架上,则电池底部和顶部之间存在 5oC 温差的情况并不少见。如果电池或单体都在同一串中,则底层的老化将或多或少与顶层的老化相同。这是因为整个电池的浮动电流都是相同的。但是,由于只有部分电池处于较高温度,浮充电流不会遵循阿伦尼乌斯方程。无论如何,生命都会减少。 当电池位于外壳中时,热管理尤为重要。理想情况下,最好使用滑道而不是架子,如果使用架子,它们应该穿孔以允许空气垂直移动。电池或单体电池应间隔开,以在所有四个侧面的单元之间提供至少 10 毫米的间隙。外壳内应提供槽或孔,使循环空气从外壳底部吹过电池,并在入口点对面的顶部排出。这也将有助于去除产生的爆炸性氢气。在电池室内使用空调的情况下,必须提供足够的空气流通,以防止电池顶部和底部之间出现温度梯度。在任何情况下,对于所有安装, 如果电池温度特别高或热管理不佳,电池可能会热失控。如果发生这种情况,整个电池将被毁坏。热失控可能在很短的时间内发生,并且在安装新电池系统仅几周后就有案例报告。 建议使用温度补偿充电设备,以最大限度地降低热失控的风险。浮动电压的降低将在一定程度上减轻带电损失,但不会完全消除影响。用户应向电池供应商咨询详细信息。 下图可用于估算在不同工作温度下在浮动系统上运行时的寿命。该图可用于估计不同的每日或每月操作温度的影响。EG,30oC 一天的效果相当于 20oC 2 天的效果。 下面是一个估算不同温度下寿命的示例。 示例:根据 IEC 60896,电池的设计寿命为 12 年,典型工作温度如下表所示: 注:12 年 = 4380 天。

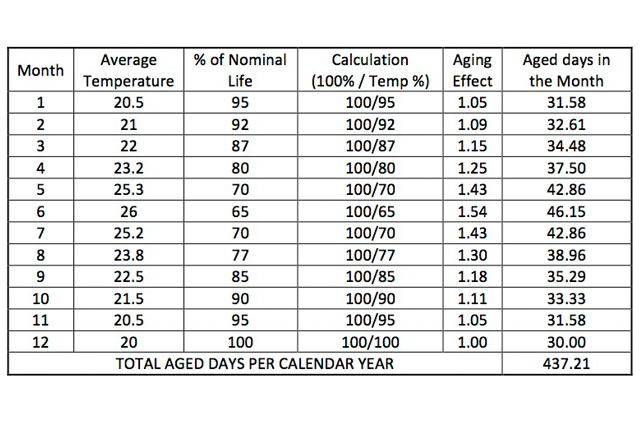

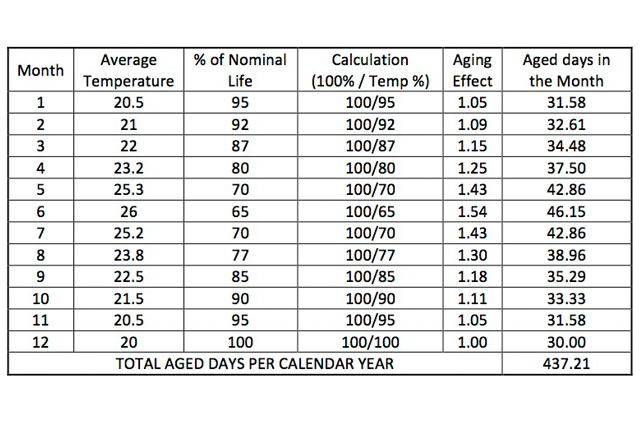

以上可以合理化为近似月平均值,如下所示: - 从下表中我们可以看出,每年电池老化 437 天而不是 365 天。因此电池将持续 4380 / 437 = 10 年而不是 12 年。

我们希望这篇最新的博文能够帮助进一步了解温度对铅酸电池的影响。我们的团队在该领域拥有丰富的经验,随时为您提供帮助,以确保为您提供尽可能最好的信息,以确保电池系统的最佳使用寿命。

YUASA battery, GS YUASA battery, GS battery

How does temperature affect lead-acid batteries?

It is well known that the life of all lead-acid batteries will be shortened when they are operated at higher temperatures. This is true of any type of lead-acid battery and whoever produces it. This effect can be described as Arrhenius equation.

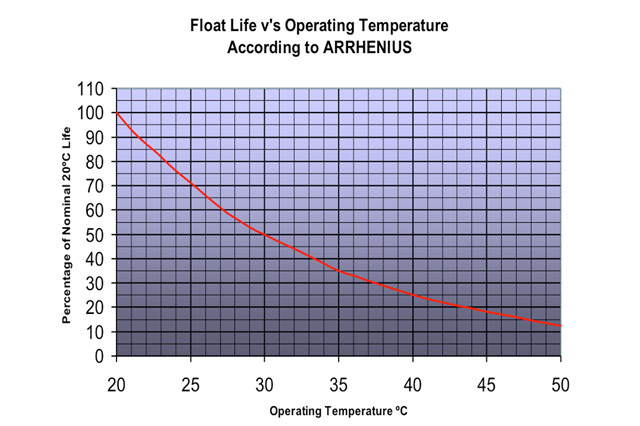

Svante Arrhenius, a Swedish scientist, found that the life of lead-acid batteries would be affected by temperature changes. He determined that every 10 o C increase in temperature would halve the battery life. Therefore, for example, if the life is 30 years at 15 o C, the life will be 15 years at 25 o C. The equation also shows that at 5 o C, the life will be 60 years, but unfortunately, when the battery is very old (usually more than 30 years), other factors will play a role, while Arrhenius equation is only valid for working batteries between about 15 o C and 40 o C.

Why does life decrease? There are many interactive electrochemical effects, but one of the main reasons is that any given constant voltage applied by the floating charger to the battery will generate floating current. If the temperature rises, the lead-acid battery will accept more current. If we accept that the end of normal life is due to grid corrosion, then if the temperature rises by 10 o C, the life will be halved, because the temperature rise will be doubled every 10 o C. It also shows that the water will evaporate through the container wall, and if the temperature rises, the evaporation will also increase. This may cause some VRLA AGM and VRLA GEL type batteries to dry out. However, this is a complex topic and cannot be easily calculated and applied to predict life. In any case, lead-acid batteries with good quality will not fail due to drying. Drying is independent of the type of ventilation. We can use Arrhenius equation to estimate the service life when the working temperature is different from the design temperature.

In Europe, the battery life under continuous temperature of 20 o C is usually quoted. If the temperature is 10 o C and lasts for 3 months, this will not reduce the total life by half, but only reduce the percentage of the expected life at 20 o C. However, if it is operated at 21 o C instead of 20 o C in the whole life cycle, the life will be reduced by nearly 10%. When we mention life, we must also be careful to distinguish "design life" from "real life". The design life of VRLA AGM battery may be 10 years, but even if it operates continuously at 20 o C, the actual life will be close to 8 years. Similarly, some people cite the design life of high-performance plant é batteries as 25 years, but there are many examples of such batteries still in use after more than 30 years.

We should also consider battery configuration and thermal management. For example, if the battery is placed on a 6-layer bracket whose height is easily more than 2m, it is not uncommon that there is a 5 o C temperature difference between the bottom and the top of the battery. If the battery or monomer are in the same string, the aging of the bottom layer will be more or less the same as that of the top layer. This is because the floating current of the whole battery is the same. However, because only some batteries are at a high temperature, the floating charge current will not follow the Arrhenius equation. In any case, life will be reduced.

Thermal management is particularly important when the battery is in the enclosure. Ideally, it is better to use slides rather than shelves. If shelves are used, they should be perforated to allow air to move vertically. The cells or individual cells shall be spaced to provide at least 10 mm clearance between the cells on all four sides. A slot or hole shall be provided in the enclosure to allow circulating air to blow through the battery from the bottom of the enclosure and exhaust at the top opposite the inlet point. This will also help to remove the explosive hydrogen generated. When air conditioning is used in the battery room, sufficient air circulation must be provided to prevent temperature gradient between the top and bottom of the battery. In any case, for all installations,

If the battery temperature is particularly high or the thermal management is poor, the battery may be out of control. If this happens, the whole battery will be destroyed. Thermal runaway may occur in a very short time, and there are case reports only a few weeks after the installation of the new battery system.

It is recommended to use temperature compensation charging equipment to minimize the risk of thermal runaway. The reduction of floating voltage will reduce the live loss to a certain extent, but will not completely eliminate the impact. The user should consult the battery supplier for details.

The following figure can be used to estimate the life of the floating system under different operating temperatures. This chart can be used to estimate the impact of different daily or monthly operating temperatures. EG, 30 o C for one day is equivalent to 20 o C for two days.

The following is an example of estimating life at different temperatures.

Example: According to IEC 60896, the design life of the battery is 12 years, and the typical operating temperature is shown in the following table: Note: 12 years=4380 days.

The above can be rationalized as an approximate monthly average, as shown below: - From the table below, we can see that the battery aging is 437 days rather than 365 days per year. So the battery will last 4380/437=10 years instead of 12 years.

We hope that this latest blog post can help us further understand the influence of temperature on lead-acid batteries. Our team has rich experience in this field and is ready to help you to ensure the best possible information for you to ensure the best service life of the battery system.

|

|